【Echo Tech】 Cut “nature”! Stone! moss! fossil! shell!

This month, we had a message from Toyohashi museum of natural history.

Toyohashi Museum of Natural History (toyohaku.gr.jp)

They wanted to test whether ultrasonic cutter ZO series works to “natural materials”.

We visited to museum with ultrasonic cutter ZO series and replacement blades.

The museum is placed in big park where Nonhoi park(zoo) and amusement park located in same places, and many families and couples comes to this park every weekend. Staffs who make us contact thought that visitors could more enjoy park if they could improve displays quality. For that, they had idea of using ultrasonic cutter to improve displays quality by processing on it.

Moss.

First we tried for removing moss, growing on stone.

Basically, we don’t recommend to use ultrasonic cutter for rock, because blade breaks easily.

For that reason and to shave stone’s surface cleanly, we selected Grinding stone for work.

We tried Plate and Bar type, and both could able to remove moss by shaving stone’s surface.

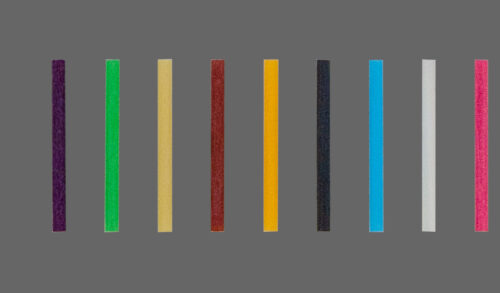

Plate type Bar type

(Test result)

Plate type・・Removes largely in each movement, but because power applied too much to material, grinding stone consumes rapidly.

Bar type・・Because bar’s width is short, it takes time to remove all moss, but it could shave surface very cleanly without making scratch.

Museum staff prefers Bar type, but we thought that favorite separates depends on workers.

Stone.

According to museum staff, generally fossil bury inside the stone. To dig up cleanly, it’s necessary to make processing little by little and finely.

This time we used ultrasonic cutter with Square pyramid ZH12. This blade’s edge is shaped very sharp and acute, that specialized for point shaving work.

Museum staff shaved rock finely with acute blade and it worked for digging.

They just used short time for this day the blade doesn’t consume, but please notice it blade might break or consumes rapidly for using on stone.

Shell.

Shell’s body is very hard as it doesn’t pass standard blade. We selected Saw blade ZH11 to saw shell forcibly. Same as standard blade, shell doesn’t pass blade when the power were not adequately applied, but when it applied power, it worked.

To use hand piece safely, please pay attention fully when you forcibly move cutter, and we do not take responsible any troubles leaded by users wrong using.

Volcanic foam.

This foam is now drifting so many around Okinawa, Japan’s ocean. It said to be made by undersea volcanic eruption. Museum staff had some samples, and their request was to remove augite from this foam.

We selected standard blade for this work, and it succeeded. Blade smoothly removes augite like sand, museum staffs were surprising with this result.

Many unfound demands!

As many materials, as many Ultrasonic cutter demands.

This means, a way of processing, proper replacement blade are different in each materials.

Even we have many materials that we never cut before, and every time we knew the answer when we test. When you are considering to get ultrasonic cutter, we would like you to consult us first. We might be your help to select proper model and replacement blades. If we could have sample of working material, we could film cutting test and send you with information, supports your decision.

Please send us your any questions or comments here. We wait for your inquiry!

worldinfo@us-dolphin.co.jp