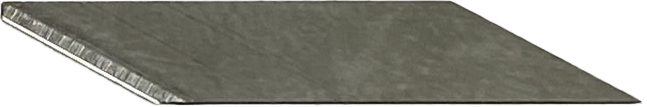

【Echo Tech】 Thin blade ZH14 & Thin long blade ZH16

Thin blade ZH14

Thin long blade ZH16

【Usable cutter model】

ZO-91 & ZO-95

Do not use with High and S-High power mode.

【Size】

ZH14 L23.5×H4×W0.15(mm)

ZH16 L25×H4×W0.15(mm)

※When it set on handpiece, the length will be 11mm shorter.

【Material】 SUS420

【Blade anchor】 ZH15 (for Thin blades)

【Set】5 pcs.

※Because it’s thin, it breaks or be bent easily than other blades. For your safety, we recommend wearing eye goggles.

Because of thin blades low durability, those edge’s acute part is initially removed.

It lessens plastic melting than other blades (0.4 mm thick) and makes cutting part cleaner.

We have set products (Thin blades + Blade anchor for thin blade ZH15) too.

Usages of Thin blades.

・For reducing damage and melting by cutting works.

“Thin size” blade changes work’s quality.

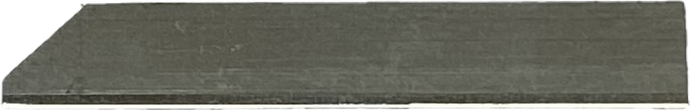

Normal blade thickness is 0.4mm (left handpiece) and thin blade is 0.15mm (right handpiece).

It’s more than half thinner than normal blade!

Thin blade can pierce object smoother because the edge (contacting side) size is small, and it connects to object’s melting reduction. It’s supportive for fine processing.

Picture of cutting test. (Left – ZO-91 Thin blade, ZO-91 Standard blade, ZO-95 Standard blade)

- Weaknesses

Thin blades break or be bent easily than other blades.

At first, we were thinking about making the blade harder, but by making it softer, it becomes bendable and hard to be broken. However, it is still not suitable for cutting forcefully.

Please wear goggles to protect your eyes.

- Cautions

Blade anchor ZH04 cannot use with thin blade because slit size is too wide and cannot fix it.

Please use ZH15 (0.2mm slit) for thin blades. - How to set a Thin Blades.

1. Turn off the power of ultrasonic cutter.

2. Remove screw on horn.

3. Replace blade and blade anchor to thin blade parts.

4. Tight screw on horn. (0.6 N・m torque level)

*Blade cuts smoother by inserting it with an angle to object or moving it back and forth.

*For cutting thick material, do not try to cut forcefully.

*Thin blades cut sharply than other blades. Be careful not to put your hands in front of the blade and make sure there is no people around.

*Do not let small children to touch blades.

Cutting material: ABS resin, 2mm

Cutting material: Wood

Cutting material: Garage kit (resin cast)

Cutting material: Plastic model

Cutting material: Light-induced modeling (3D printer output)