【Echo Tech】 How do “Welding blade and bar” weld plastic?

Our ultrasonic cutter ZO series can weld vinyl sheet and plastic, by using welding blade or bar.

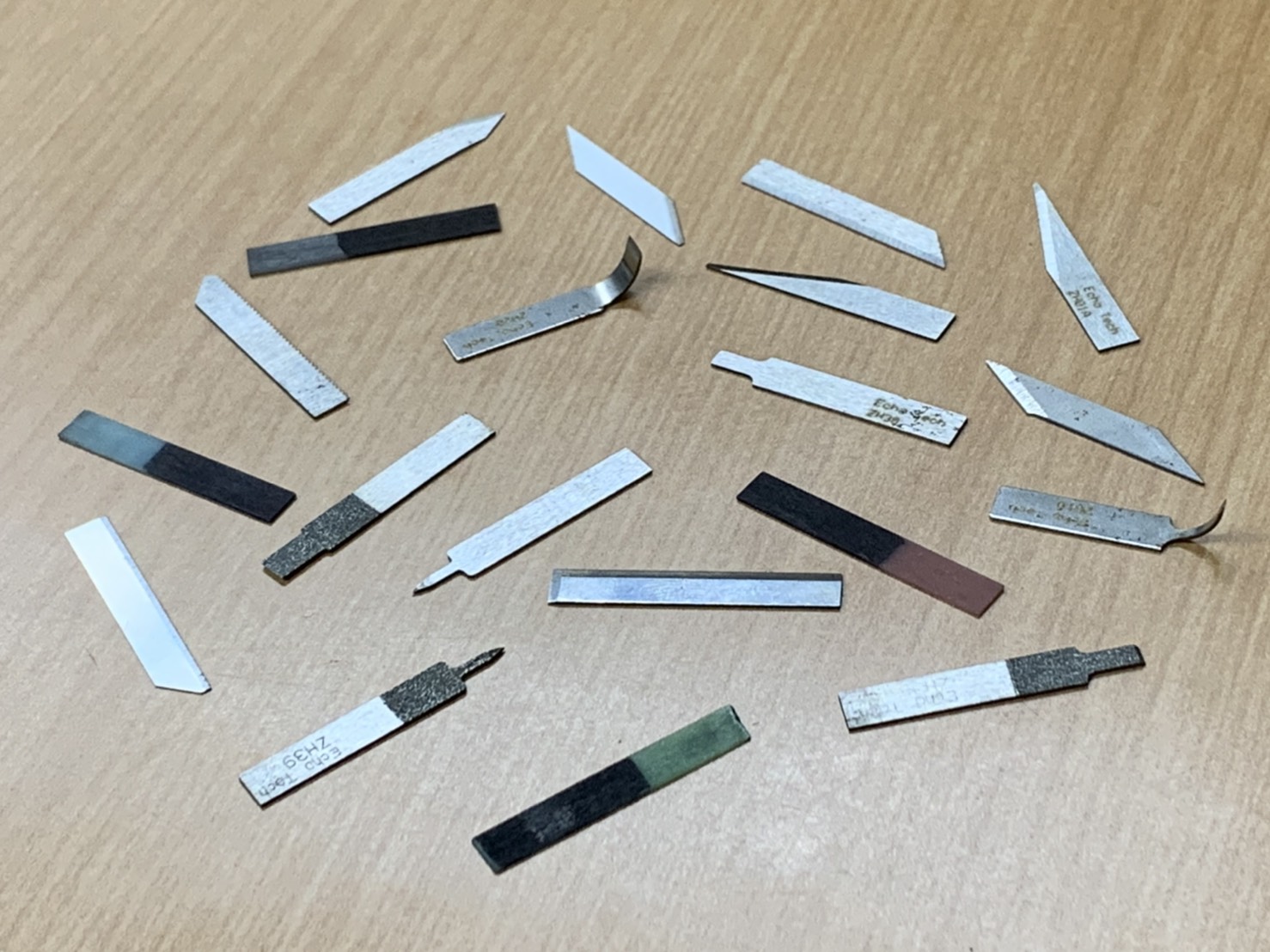

Welding blade ZH38 Welding bar ZH54

“Blades” for cutting work, enhances it sharpness by vibration power that vibrates blade and extend movement of blade’s width.

How about “Weld”?

How do ultrasonic vibration enhances welding power?

What is different between “Bar” and “Blade” type?

Mechanism of “welding”

When ultrasonic has transmitted to the blade, blade vibrates so speedily.

(Ultrasonic cutter ZO series = 40kHz = vibrates 40,000 times every per second)

Vibration transmitted on blade generates “Friction” and become to “Heat” by touching to things. This “Heat energy” is a key of welding.

Contact section between blade or bar, and work material, the heat generates and melt surface of duplicated work material. Melted work material loses its shape become close to liquid while ultrasonic were transmitted. It combines again and be solidify when it loses heat.

To sum up, “Welding work” proceeds,

Melt materials(become liquid) → mix(combine) → get harden(weld)

Welding blade ZH38

Blade type is useful for sheet welding.

Blade type’s tip shaped squarely and flat. You could weld like writing line on material.

Ultrasonic energy transmitted on the blade type, concentrates on blades edge part.

Because ultrasonic retains tip face, it could weld in wide range and powerfully, compared with bar type.

Conversely, it’s not specified for thick materials which might melt largely.

Welding bar ZH54

Bar type is useful for plastic board welding.

Conventionally, plastic work materials welded by blade type got big melt because the heat hardly transmits to back side board. When it welded in line, melted plastic sticks on blade and surface gets mess.

We developed this bar type to solve those problems. You just make spot weld on duplicated plastic board, and you could easily weld it. Ultrasonic energy reaches to back side plastic and weld.

If you have any questions or comments, send us message here.

worldinfo@us-dolphin.co.jp