【Echo Tech】 Welding series ZH38 & ZH54

Welding blade ZH38

Welding bar ZH54

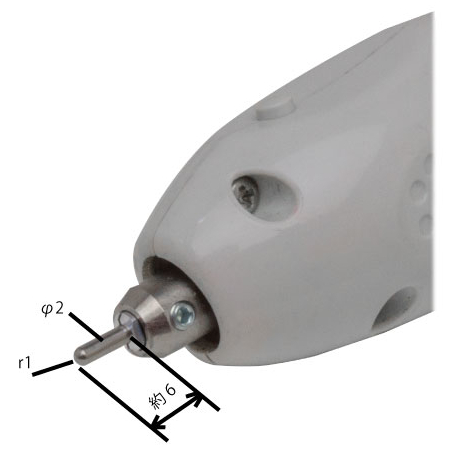

【Usable cutter model】

ZO-91 & ZO-95

Do not use with S-High power mode.

【Size】

ZH38 L25×H2 (edge)×W0.4 (mm)

ZH54 L17×H2 (edge)×W2 (mm)

※When it set on a handpiece, the length will be 11mm shorter.

【Material】

ZH38 High Speed Steel (SKH)

ZH54 Titanium

【Blade anchor】

ZH38 → Blade anchor ZH04

ZH54 → Bar anchor ZH53

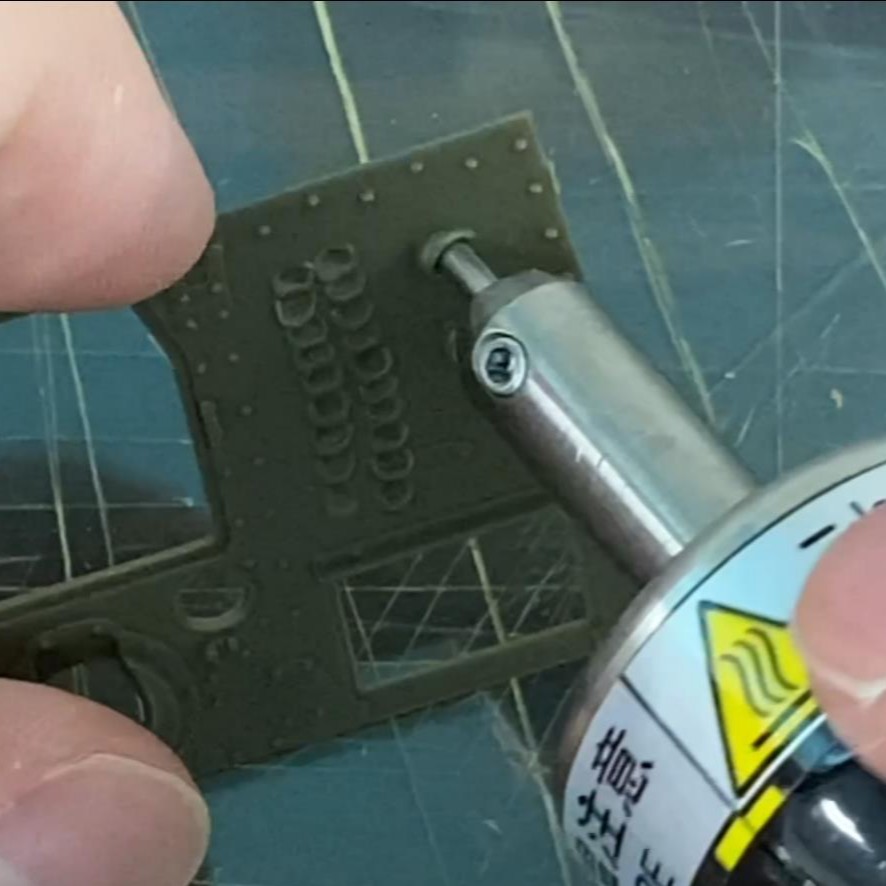

Usage of Welding blade & bar.

This replacement blade was developed for melting and welding film. Like the flat blade, it lacks a blade and is actually the exact same size as the 2mm flat blade, including the blade length. However, unlike the flat blade, the corners at the contact point are rounded, resulting in a smoother weld. The welding force is also reduced, allowing it to melt and press thin materials like vinyl, but welding materials the thickness of a clear file is difficult.

Welding is a processing method that melts and bonds materials. When welding PP (polypropylene) bags, the blade is pressed directly from above, applying a slight amount of pressure to melt the contact surface. Perhaps due to the difference in the blade processing method, the melting occurs more slowly than with other replacement blades. By pressing at regular intervals and creating perforations, the adhesive strength at the welded area is weakened, making it visually easier to open and potentially useful for packaging or temporarily fastening small items. Of course, if the appearance of the welded area is not a concern, you can continue processing to achieve a complete weld.