【Echo Tech】 What’s the merit of adopting Ultrasonic cutter ZO series instead of normal cutter?

We are calling Ultrasonic cutter ZO series, “time-shortening tool”.

Cuttable materials of ultrasonic cutter and normal cutter is same.

Ultrasonic energy transmitted to blade enhances sharpness and able to cut materials speedily.

This cutting speed (sharpness) is the biggest different point compared with normal cutter.

What other merits are in Ultrasonic cutter ZO series?

Need outlet for using.

Ultrasonic cutter ZO series is electric appliance.

It needs to connect power cord to have supplied electricity.

Compact size normal cutter is convenient for bringing and use at anywhere.

Ultrasonic cutter ZO series is proper for using at home.

Risk of Injury.

Decrease of injury risk is one of good feedback which we most hear from users.

Have you ever experienced that your held cutter has accidentally passed when you try to cut hard material? It occurs due to applying excessive power on cutter.

Ultrasonic cutter doesn’t need power because the sharpness (power) is capable for cut without applying power.

Also, when it cut meltable materials such as plastic, melted part holds proceeding blades and support not to jump suddenly.

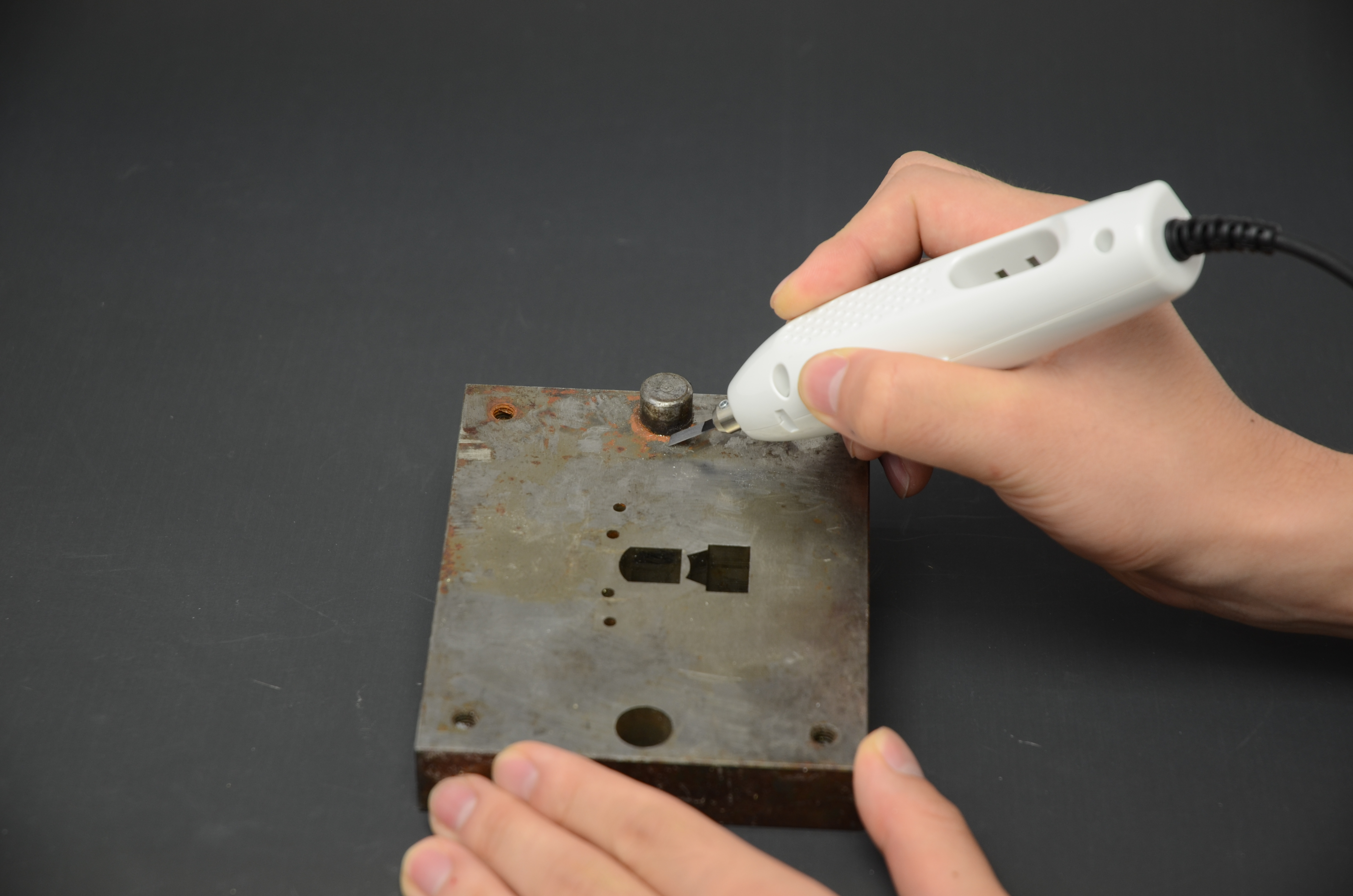

“Cut”, “Weld” and “Polish”.

Applying ultrasonic energy, it able to do works, Weld and Polish for some materials.

(Vinyl weld – Welding blade) Corresponded material/ Vinyl, Plastic

(Mold polish – Grinding stone) Corresponded material/ Metal

Replacement blades.

Ultrasonic cutter ZO series has over 40 types of blades.

Saw, rounded, L shape, acute, thin, etc.

Each blade is corresponding to various works. Users choose blade by themselves which they think it’s proper for their work.

Totalize.

Normal tool → For cutting easy materials or outdoor use.

Ultrasonic cutter → For cutting hard materials in indoor.

For any questions or comments, please send us messages here!

worldinfo@us-dolphin.co.jp